Inside the exacting sphere of wiring architectures, busbar manipulation introduces special problems. Ranging from precise construction over smooth implementation, every part necessitates detailed care and novel techniques. Up-to-date production systems have reshaped busbar creation, offering outstanding productivity and proficiency. Modernized tools such as automatic slitting, turning, and joining platforms secure accuracy, reproducibility, and trimmed completion periods.

These breakthroughs effect actual payoffs for clients. Busbar constructs are developed promptly and reliably, decreasing interruptions and promoting on-schedule accomplishment. Alongside, the elemental correctness of state-of-the-art protocols results in busbars with boosted transmission performance and durability, delivering constant power flow throughout lifespan.

- Robotic cropping: Accurate sectioning techniques secure correct and consistent measurements, lowering discard and amplifying general output

- Bending Expertise: Advanced bending systems create precise bends and angles, allowing for complex busbar designs and customized configurations

- Fusing ability: Computerized bonding techniques deliver solid and dependable attachments, maintaining busbar unit integrity

By integrating these advanced methods, enterprises could improve busbar production workflows, attaining unrivaled capability and output. The evolution of electric grids evolves through novel ideas, spotlighting state-of-the-art busbar fabrications as leaders.

Detailed Copper bar Twisting dedicated to Electrical Distinction

Attaining supreme electric effectiveness demands accurate and detailed conductor shaping skills. Conductive bars, the primary elements conveying energy, need to be fashioned with outstanding exactitude to ensure high-quality power transmission and limit resistance. This detailed care is key to blocking temperature increases and probable degradation of electronic systems. With modern forming machines paired with professional skills, creators construct conductors matching hard demands in different energy implementations.

- Superior energy transmission

- Trimmed current decay

- Enhanced network dependability

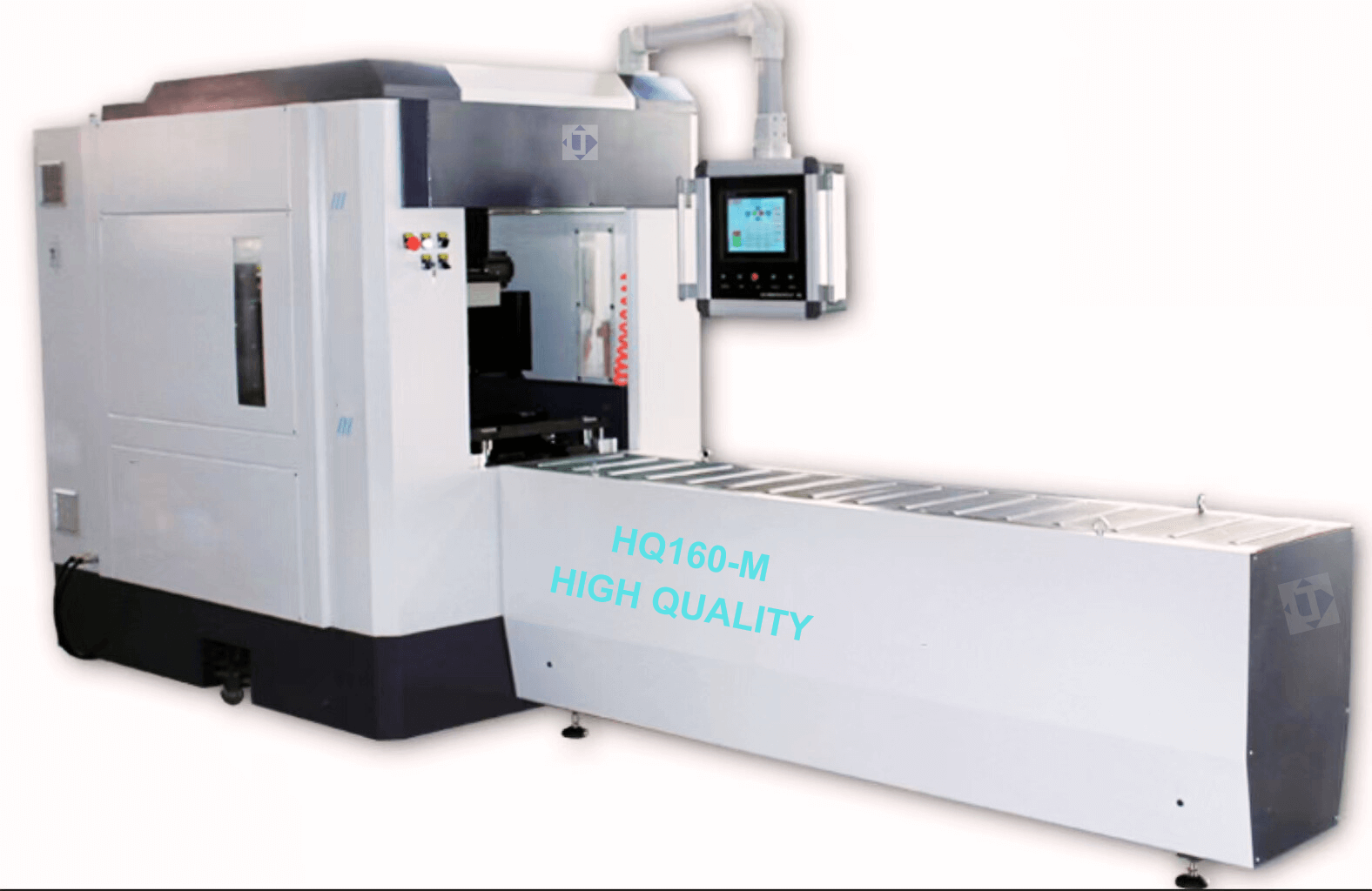

Enhance Specified Busbar Manufacturing deploying a hybrid fabrication system

Do you look for a strong system to oversee your current bar assembly requirements? Look no further than the innovative 3-in-1 Busbar Machine! This multifunctional apparatus incorporates three main features in one machine, supplying an all-encompassing method for cropping, shaping, and marking current bars with excellent exactness.

- Asset 1

- Advantage 2

- Merit 3

Made for strength along with user-centric function, the all-in-one electric equipment plans to supply flawless outputs while limiting pauses. Strengthen your charge carrier production directly through this important system!

Intelligent Electrical bar Construction: Maximizing Throughput and Carefulness

The creation business regularly aims to elevate capacity and exactitude. Power strip manufacturing, a fundamental task in energy engineering, mirrors this. Digitized copper strip processing machines are evolving standards by markedly amplifying performance while assuring superior consistency. These progressive operations apply modern equipment such as computerized control and laser slicing technology to construct electrical bars with superb consistency and pace.

By automating repetitive tasks, these systems free human workers to focus on more value-added activities. Such refinements amplify broad effectiveness and reduce imperfections, crafting first-class electrical bar elements. Moreover, robotized conductor fabrication platforms provide enhanced tracking and information evaluation facilities, yielding meaningful understanding into production workflows and enabling ongoing optimization.

State-of-the-Art Current bar Treatment Innovations

The appetite for advanced electric networks expands demanding better current bar machining. State-of-the-art machinery is advancing reforming this sector, facilitating crafting of remarkably accurate and competent electrical bars. These breakthroughs comprise cutting practices like optic ablation and electrical spark machining (EDM), ensuring improved precision, finishing work, and substrate cutting. Besides that, the amalgamation of CAD and CAM systems supports refined supervision of structure and suppresses loss

- Mechanized operations in busbar machining streamline production, increasing efficiency and reducing lead times|Automated apparatuses in conductor manufacturing optimize workflows, boosting productivity and cutting delays|Mechanized tools in power strip fabrication enhance output, augmenting speed and minimizing downtime|Computerized devices in current bar assembly improve cycles, elevating effectiveness and shortening turnarounds|Digitized systems in copper bar processing advance throughput, maximizing rapidity and trimming wait periods|Robotic equipment in electric contact crafting upgrade sequences, heightening competence and limiting stoppage|Intelligent machines in charge carrier production refine operation, increasing capacity and lowering processing times|Streamlined units in electrical bar treatment boost productivity, accelerating results and decreasing idle intervals

- Detection tools play a crucial role in ensuring the quality and consistency of machined busbars, detecting any deviations from specifications|Observation gadgets hold vital importance in maintaining integrity and uniformity of fabricated conductors, identifying anomalies relative to standards|Measurement technologies serve critical functions in preserving excellence and regularity of manufactured power strips, pinpointing divergences against criteria|Detection instruments perform key roles in upholding precision and stability of constructed current bars, recognizing variants from requirements|Tracking mechanisms are essential in securing accuracy and uniformity of processed copper strips, signaling disparities from benchmarks|Evaluation tools have importance in guarding fidelity and steadiness of crafted electric contacts, flagging inconsistencies to parameters|Monitoring devices are instrumental in affirming reliability and evenness of assembled charge carriers, spotting departures from norms|Data analytics systems are fundamental in assuring quality and homogeneity of machined electrical bars, marking deviations against specifications

Enhancing Charge carrier Production with Advanced Equipment Enhancing

Throughout growing electrical setups, advancing electric contact creation is indispensable. Modern advancements in manufacturing equipment have revolutionized this process, enabling manufacturers to produce high-quality busbars with increased efficiency and precision. High-speed automated cutting systems ensure accurate and consistent dimensions, in addition exquisite binding equipment furnish robust and sure fastenings. This progress realizes trimming manufacturing spans plus decreasing raw substance losses, enhancing ecological responsibility.

The Rise of Automation in Busbar Manufacturing

Conductor fabrication undergoes a significant change due to implementing robotic processes. Intelligent machinery optimizes steps covering trimming and contouring through bonding and evaluation. Such transition yields numerous advantages including higher throughput, enhanced output excellence, lowered staffing expenses, and fewer defects.

- Therefore, power strip makers create premium items more rapidly, fulfilling stringent demands of multiple fields

- {Furthermore, automation enhances workplace safety by reducing manual labor involving workers to potentially hazardous conditions|Moreover, robotics improves occupational health lowering physical tasks exposing staff to risky environments|Additionally, intelligent systems boost labor protection by minimizing manual efforts subjecting employees to unsafe situations|Besides that, computerized operations augment workforce security by cutting down physical jobs placing workers in dangerous settings|Further, mechanized functions uplift occupational safety by decreasing manual duties involving personnel in harmful conditions|Also, digitized procedures raise workplace protection by lessening human effort exposing laborers to hazardous areas|Likewise, automated workflows increase employee security by limiting manual tasks facing crew to risky circumstances|Similarly, streamlined processes improve staff safety by reducing physical labor subjecting workers to perilous zones

As technology advances, power strip production using robotics is foreseen to develop continuously

State-of-the-Art Charge carrier Crafting Instruments

Across electricity engineering, state-of-the-art copper bar processing units are necessary for fabricating stable and productive circuitry layouts. Sophisticated equipment adopts modern inventions to operate electric contacts with outstanding precision and speed. Encompassing marking and cropping as well as curving and fashioning, these multifaceted apparatuses conduct varied operations with exactness, ensuring prime results and sturdiness of products. Integrating resilient substances with cutting-edge command systems helps these machines perform flawlessly and steadily during harsh situations

- Computerized control systems ensure precise alignment of busbars throughout the processing cycle|Smart regulation frameworks guarantee accurate positioning of conductors during entire fabrication operations|Programmable management solutions provide exact arrangement of power strips throughout production sequences|Computer-aided supervision platforms deliver precise orientation of current bars across processing steps|Mechanized monitoring tools secure accurate setup of copper strips during manufacturing phases|Digitized adjustment apparatuses facilitate exact alignment of electric contacts through assembly stages|Robotic command mechanisms maintain precise positioning of charge carriers during fabrication runs|Streamlined control devices assure accurate layout of electrical bars throughout machining procedures

- Heavy-duty construction withstands the rigors of continuous operation in industrial settings|Solid manufacturing sustains harsh demands of nonstop use in factory environments|Hardy fabrication endures stresses of prolonged function within production areas|Reinforced design tolerates strains of sustained activity under workshop conditions|Stout assembly resists impact of relentless service inside industrial facilities|Tenacious build copes with pressures of endless operation in manufacturing plants|Resistant structure faces challenges of unceasing work across factory contexts|Hardwearing framework stands up to trials of nonstop performance in production sites

- High-Speed processing reduces production time and increases overall productivity|Effective machining shortens manufacturing periods and boosts total output|Quick fabrication lowers operation duration and heightens aggregate yield|Speedy manufacture cuts assembly intervals and enhances combined efficiency|Accelerated production diminishes process time and advances broad throughput|Expedited creation truncates working spans and improves overall performance|Prompt processing contracts operational lengths and raises total capacity|Fast development shrinks fabrication cycles and escalates general productivity

Applying innovative electrical bar crafting technology has transformed fabrication standards, promoting fabrication of enhanced, durable power networks addressing growing requirements of current electrical applications.

Innovative Electric strip Folding serving Refined Schemes

In the ever-evolving landscape of electrical engineering, precision in component fabrication is paramount. Copper bars, indispensable routes passing electricity, repeatedly need refined molding configurations to comply with varying functions. Standard flexing approaches commonly underperform with elaborate configurations, producing poor outcomes. Embracing modern copper bar folding machinery reforming processes by shaping elegant contours with excellent adjustability.

- Incorporating fresh CNC technology, these enhanced tools secure impeccable replication across curvatures

- The code running these apparatuses includes straightforward controls, facilitating engineers to build sophisticated folding layouts comfortably

- Besides that, the systems efficiently cooperate with varied materials, enlarging its coverage across multiple factory sectors

The breakthrough in electric contact bending helps technicians to realize elaborate plans, achieving enhanced power flow and minimized manufacturing charges.

Harnessing Success with the help of 3D Busbar Fabrication

{Revolutionizing power distribution systems, 3D busbar fabrication offers an innovative approach to optimize efficiency and performance|Transforming energy transmission networks, three-dimensional conductor crafting provides a novel method to enhance productivity and output|Changing electric supply architectures, 3D power strip making introduces a fresh path to boost effectiveness busbar punching bending cutting machine and results|Updating circuitry distribution frameworks, three-dimensional current