When dealing with advanced rib tube construction and fabricating, working with authentic experts is crucial. These seasoned ribbed tube making experts possess a extensive grasp of thermal management principles, substance attributes, and the state-of-the-art approaches for creating effective heat exchangers. They handle everything from conceptualization and testing phase to wide-scale creation and careful assessment. Adopting the right patterned pipe building technician can significantly impact the efficiency and longevity of your mechanism.

Next-generation Textured Cylinders

Leading-edge factory deployments frequently demand notably efficient temperature transmission, and optimized finned hollow bodies are indispensable to achieving this. These units contain meticulously designed groove geometries, usually utilizing involved formulas to boost the extent available for thermal exchange. Building practices may feature extrusion, joined by detailed fin modeling and intermittently a particular surface covering to supplementarily boost capability. Electing the right finned line structure is influenced on the definite functional modes, namely media parameters, temperature conditions, and pressure degrees.

Exclusive Ribbed Copper Channel Systems

Handling challenging temperature management conditions? Our expert team creates heat-sinked copper line systems precisely custom fit for your application. We utilize advanced assembly techniques and precise calculations to enhance power dispersion efficiency. Whether you're in the engineering-related sector, or need superior cooling aimed at a complex mechanism, our augmented copper tubing can supply strengthened output. We examine factors such as flowing agent circulation rates, background temperatures, and spatial constraints designed for design a truly personalized and efficient solution.

Technicians in Profiled Aluminum Tube Methods

For years, we've been dedicated to providing unparalleled expertise in textured aluminum conduit design, development, and integration. As leading specialists, we offer a comprehensive suite of services, catering to a broad spectrum of industries, including temperature regulation, power output, and synthetic processing. Our workforce of trained engineers exhibits a comprehensive understanding of heat dispersion principles and constituent science, ensuring that every operation we undertake delivers optimal quality and stability. We hold confidently ourselves on delivering personalized methods that precisely satisfy our clients’ unique needs. Whether you require radiator repair, installation, or a all-in-one system configuration, our focus to excellence remains unwavering. Contact us today to consult your customized problems.

Extended Tube Design and Help Provision

Improving thermal transfer efficiency is paramount in countless areas, and that's where specialized augmented tube engineering and advisory provisions truly shine. We offer comprehensive solutions encompassing everything from initial thought to full-scale execution. Our group of experienced masters leverage advanced replication techniques and industry best systems to formulate customized upgraded tube systems for a wide array of sensitive environments. Whether you're seeking to raise efficiency, alleviate fuel costs, or fix specific system issues, our upgraded tube expertise ensures best results. We in addition offer routine service facilities to preserve lasting working integrity.

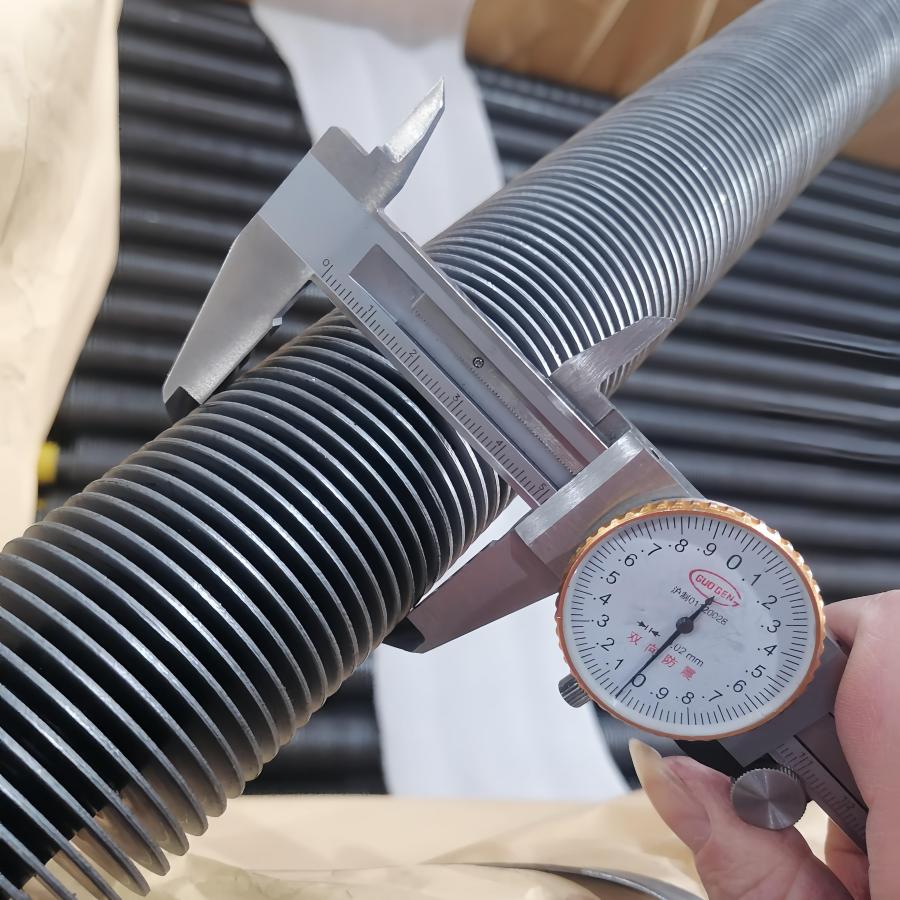

Leading Precision Profiled Tube Building

The needs of modern heat migration systems are causing a progression towards highly precise textured tube techniques. Traditionally, common fin designs were tolerable, but now applications in gadgets and energy processing necessitate particularly tight tolerances and complex geometries. This involves meticulous manufacturing of fins directly onto the tube blank, often utilizing high-tech frosty manufacturing equipment to procure the desired fin extent, clearing, and shape. Additionally, the element selection plays a crucial position, with exclusive fusions frequently utilized to increase thermal productivity while maintaining structural durability. Benchmark verification procedures are also critical to maintain unvarying extended tube quality.

Extended Copper Pipe for Heat Exchangers

Contemporary heat conduction systems frequently apply finned copper line as a crucial ingredient in heat exchangers. The implementation of fins, typically made from metal, significantly expands the surface extent available for heat conduction, leading to a increased efficient heat circulation. These augmented copper tubing are widely found in astm b171 applications ranging from industrial processes, such as chilling machinery, to home HVAC systems. The excellent thermal heat flow of copper, matched with the augmented surface zone provided by the fins, causes in a significantly effective method for regulating heat. Different fin configurations, including planar and curly, deliver varying degrees of performance enhancement depending on the certain application’s demands.

Contemporary heat conduction systems frequently apply finned copper line as a crucial ingredient in heat exchangers. The implementation of fins, typically made from metal, significantly expands the surface extent available for heat conduction, leading to a increased efficient heat circulation. These augmented copper tubing are widely found in astm b171 applications ranging from industrial processes, such as chilling machinery, to home HVAC systems. The excellent thermal heat flow of copper, matched with the augmented surface zone provided by the fins, causes in a significantly effective method for regulating heat. Different fin configurations, including planar and curly, deliver varying degrees of performance enhancement depending on the certain application’s demands.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum ribbed tubes offer a compelling combination of low-weight construction and remarkable efficiency, making them ideal for a comprehensive range of operation heat transfer operations. Their unique composition—featuring aluminum grooves attached to the tube outer layer—significantly boosts the heat exchange ability without adding substantial bulk. This translates to shrunk energy outlays and improved overall machinery consistency. Consequently, these tubes are frequently chosen in HVAC systems, refrigeration, and other heat dispersion processes where minimizing burden and maximizing caloric transfer are paramount factors.

Finned Tube Constituent Options: Brass & Al

When favoring finned tube fabric, engineers frequently weigh copper and aluminum. Copper offers exceptional rusting protection and superior power flow, making it appropriate for applications where efficient heat distribution is paramount, such as in refrigeration systems systems. However, copper's enhanced valuation and probable for galvanic corrosion with other metals can be limiting barriers. Conversely, aluminum provides a significantly lower valuation and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Refining Heat Transfer with Finned Sections

The productivity of heat exchangers frequently hinges on the design and execution of finned channels. These structures significantly magnify the surface area available for heat dispersion, allowing for a much greater removal of heat compared to simple, unfinned conduits. The maximization process involves a complex interplay of factors, including fin form – such as fin elevation, spacing, and size – as well as the fabric of both the fins and the fundamental conduits themselves. Careful consideration of the material flow characteristics, whether it's air or a molecule, is also paramount to ensure that the heat dispersion isn’t restricted by boundary layer effects or uneven allocation of the working mass. Ultimately, a well-designed finned channel array delivers a important improvement in overall thermal output within a given space.

Hardy Finned Tube Solutions for Engineering Applications

Meeting the needs of demanding process environments necessitates reliable heat movement systems. Our finned tube solutions are engineered for exceptional effectiveness, providing uniform heat transmission in a range of applications, from chemical-processing processing to ventilation control. Constructed from finest materials and featuring advanced corrosion defense techniques, these modules minimize maintenance downtime and maximize operational efficiency. The tailored fin geometry promotes increased heat distribution, even under demanding operating situations.