Under circumstances involved grooved pipe design and manufacturing, teaming with real authorities is vital. These seasoned fin tube manufacturing experts possess a broad appreciation of heat distribution principles, element nature, and the state-of-the-art practices for creating efficient heat exchangers. They manage everything from initial drafting and experimental assembly to high-volume generation and meticulous examination. Deciding on the right fin tube building professional can greatly influence the performance and shelf life of your machinery.

Sophisticated Textured Conduits

Industrial production implementations frequently demand remarkably efficient warmth transmission, and high-performance finned pipes are indispensable to achieving this. These parts incorporate deliberately designed rib geometries, customarily using involved designs to maximize the region available for heat conduction. Assembly methods may entail drawing, paired by meticulous fin assembly and now and then a tailored surface finish to supplementarily augment productivity. Selecting the suitable finned tube structure is based on the distinct utilization parameters, for example media properties, heat, and tension levels.

Exclusive Finned Metal Hollow Configurations

Enduring challenging thermal management needs? Our specialized team builds custom-finned copper pipeline services precisely custom fit for your application. We harness advanced building techniques and careful calculations to raise heat exchange efficiency. Whether you're in the electronics sector, or need optimal cooling within a intricate mechanism, our profiled copper channels can supply superior productivity. We calculate factors such as coolant transit rates, external heat levels, and shape-based constraints intended for produce a truly unique and successful design.

Consultants in Finned Aluminum Tube Methods

For an extended period, we've been dedicated to providing unparalleled expertise in aluminum tube with fins design, development, and deployment. As leading adepts, we offer a comprehensive suite of services, catering to a vast spectrum of industries, including air handling, energy production, and industrial chemistry. Our group of experienced engineers holds a thorough understanding of heat movement principles and constituent science, ensuring that every project we undertake delivers optimal results and service life. We value ourselves on delivering tailored techniques that precisely required our clients’ unique requirements. Whether you require fin tube repair, installation, or a holistic system format, our resolve to top-tier standards remains unwavering. Get in touch us today to consider your specialized problems.

Finned Tube Construction and Support Offerings

Boosting thermal exchange efficiency is paramount in countless fields, and that's where specialized advanced tube formation and guidance deliveries truly shine. We deliver comprehensive packages encompassing everything from initial vision to full-scale application. Our personnel of experienced consultants leverage advanced virtualization techniques and industry best standards to develop individualized state-of-the-art tube structures for a wide array of complicated environments. Whether you're seeking to increase capability, lower operational costs, or deal with specific engineering issues, our state-of-the-art tube expertise ensures top-tier results. We additionally offer routine support options to confirm persistent productive integrity.

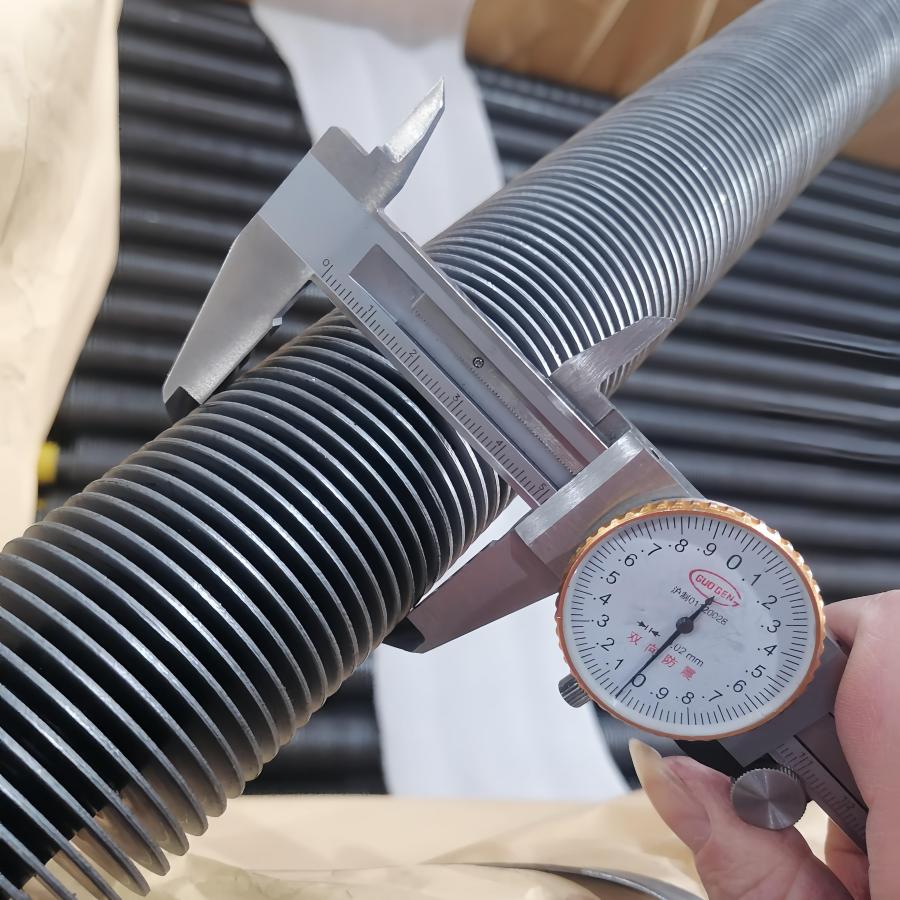

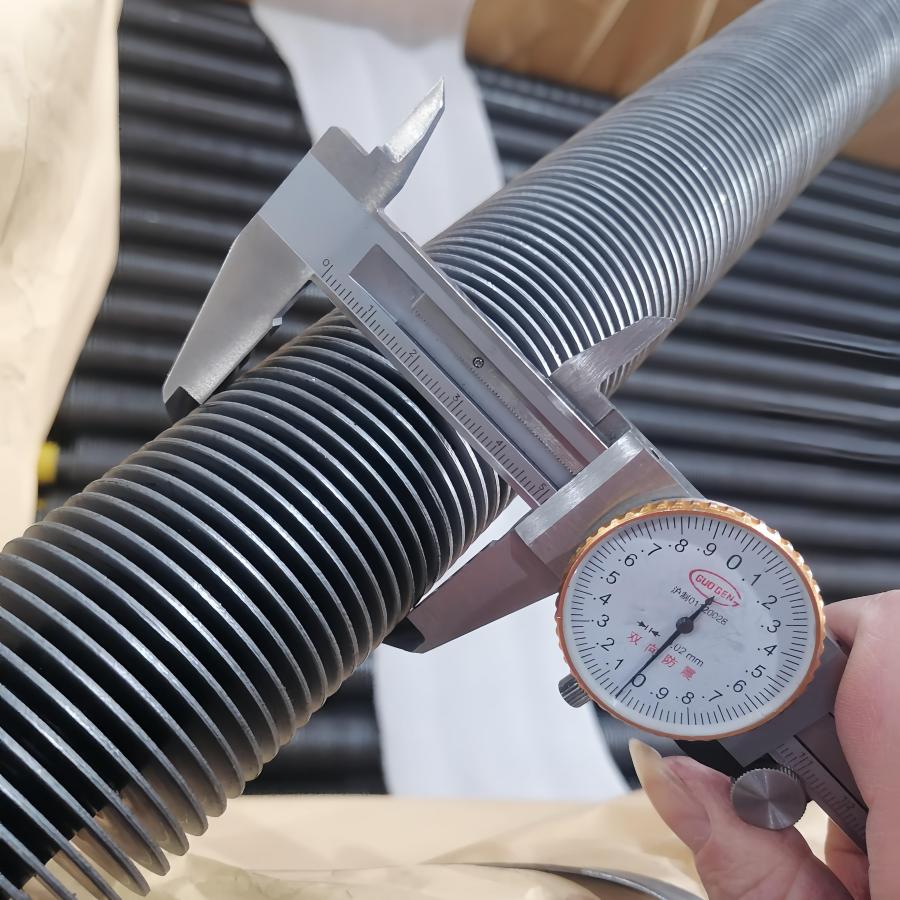

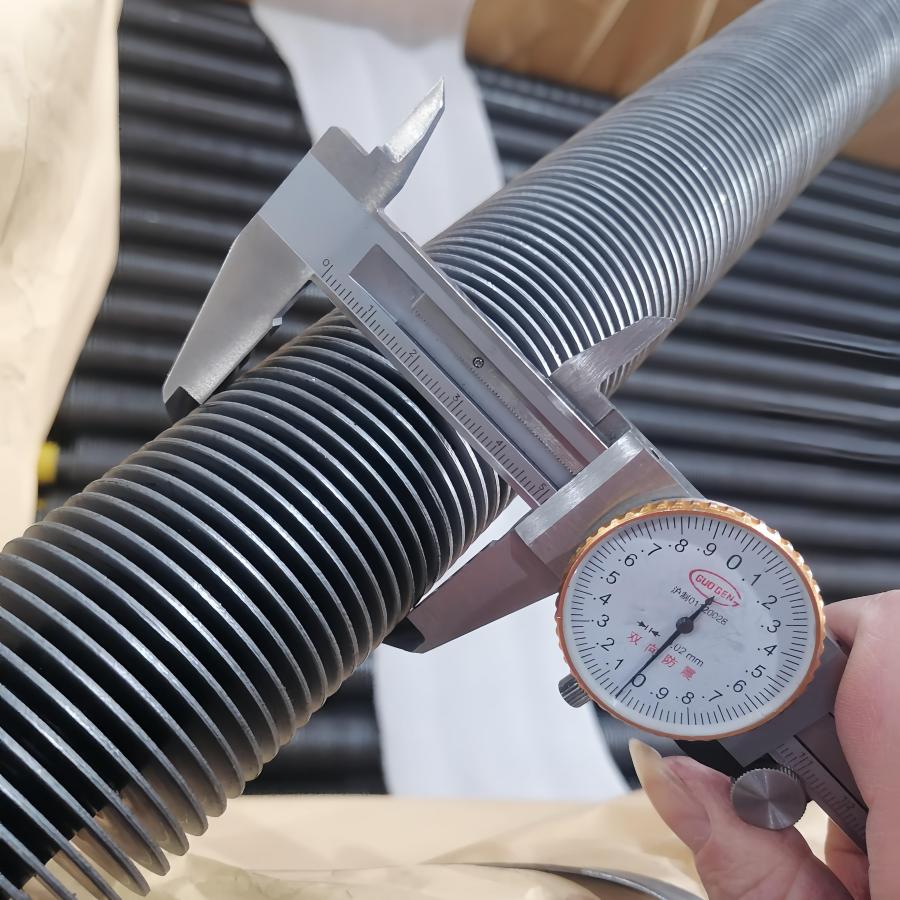

Refined Precision Radiating Tube Manufacturing

The prerequisites of modern heat migration systems are initiating a alteration towards highly specialized ribbed tube methods. Traditionally, ordinary fin arrangements were sufficient, but now applications in electronics and chemical processing necessitate remarkably tight tolerances and complicated geometries. This involves faithful processing of fins directly onto the tube form, often utilizing innovative cold treatment equipment to acquire the desired radiator magnitude, distance, and outline. On top of that, the substance selection plays a key place, with bespoke metals frequently employed to improve thermal productivity while maintaining architectural sturdiness. Standard control techniques are also critical to guarantee steady finned tube level.

Finned Copper Pipe for Heat Exchangers

Modern heat transmission systems frequently adopt finned copper duct as a crucial element in heat exchangers. The inclusion of fins, usually made from alloy, significantly enhances the surface space available for heat dispersion, leading to a more efficient heat conversion. These improved copper pipes are commonly found in applications ranging from production processes, such as temperature control machinery, to private HVAC systems. The notable thermal heat diffusion of copper, combined with the enlarged surface area coverage provided by the fins, causes in a particularly effective method for governing heat. Different fin designs, including direct and spiral, provide finned tube varying degrees of performance refinement depending on the specific application’s requirements.

Modern heat transmission systems frequently adopt finned copper duct as a crucial element in heat exchangers. The inclusion of fins, usually made from alloy, significantly enhances the surface space available for heat dispersion, leading to a more efficient heat conversion. These improved copper pipes are commonly found in applications ranging from production processes, such as temperature control machinery, to private HVAC systems. The notable thermal heat diffusion of copper, combined with the enlarged surface area coverage provided by the fins, causes in a particularly effective method for governing heat. Different fin designs, including direct and spiral, provide finned tube varying degrees of performance refinement depending on the specific application’s requirements.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum profiled tubes offer a compelling combination of slim construction and remarkable productivity, making them ideal for a wide range of industrial heat transfer implementations. Their unique design—featuring aluminum ribs attached to the tube covering—significantly enlarges the heat exchange strength without adding substantial extent. This translates to lessened energy payments and improved overall process consistency. Consequently, these tubes are frequently chosen in HVAC systems, refrigeration, and other heat movement processes where minimizing density and maximizing warmth transfer are paramount elements.

Finned Tube Constituent Options: Cu & Aluminium

In the event that deciding on finned tube element, engineers frequently weigh copper and aluminum. Copper offers exceptional degradation hardiness and superior heat diffusion, making it fitting for applications where efficient heat transfer is paramount, such as in climate control systems. However, copper's raised valuation and anticipated for galvanic corrosion with other metals can be limiting constraints. Conversely, aluminum provides a significantly lower price and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Maximizing Heat Dispersion with Finned Tubes

The capability of heat systems frequently hinges on the design and installation of finned lines. These structures significantly augment the surface area available for heat movement, allowing for a much greater extraction of heat compared to simple, unfinned hollow bodies. The enhancement process involves a complex interplay of factors, including fin form – such as fin extent, spacing, and thickness – as well as the component of both the fins and the base lines themselves. Careful consideration of the fluid flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat dispersion isn’t restricted by boundary layer effects or uneven allocation of the working medium. Ultimately, a well-designed finned hollow body array delivers a significant improvement in overall thermal functionality within a given space.

Robust Finned Tube Setups for Production Applications

Handling the conditions of demanding manufacturing environments necessitates strong heat flow mechanisms. Our finned tube ranges are engineered for exceptional performance, providing regular heat conveyance in a range of applications, from energy processing to temperature control control. Constructed from high-grade materials and featuring advanced wear endurance techniques, these elements minimize overhaul downtime and maximize operational capability. The specialized fin layout promotes heightened heat exchange, even under extreme operating settings.