Widely recognized Rotational mass flow gauges due to their unmatched accuracy. These devices depend on Coriolis-induced lateral forces affecting rotating elements. Fluid mass rate is ascertained by monitoring shifts in vibrating pipe segments triggered by fluid passage. Highly suitable for demanding fluids, including sticky or heavy-flowing liquids.

- Moreover, their ability to handle a wide range of flow rates and temperatures makes them ideal for diverse applications in industries such as

- petrochemical production

- where precise fluid measurement is paramount.

Understanding Coriolis Flow Measurement Tools

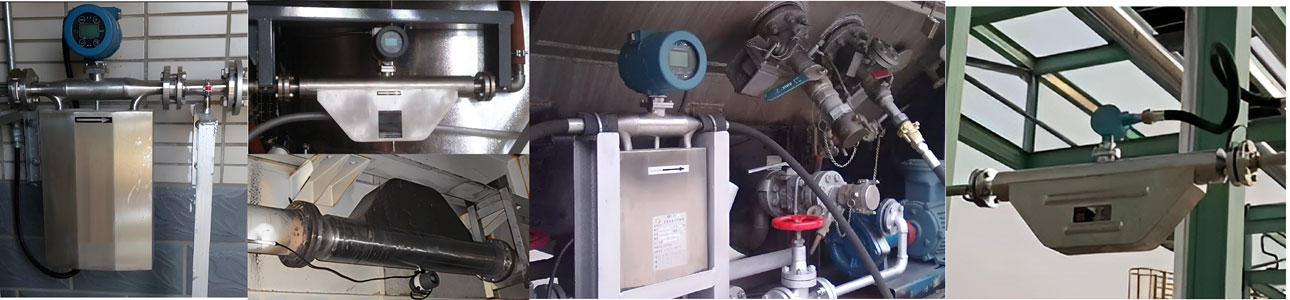

Coriolis force measuring instruments perform as a vital tool in various industrial processes. The instruments deploy the principle of the Coriolis effect to scrupulously measure the mass flow rate of materials. When a fluid flows through the meter, it experiences an inertial force due to its rotation within a curved tube. prompts a measurable alteration in the fluid's path, proportionally matches proportional to the mass flow rate. Coriolis effect mass flow meters boast high accuracy, repeatability, and wide measurement ranges, making them suitable for applications requiring precise flow control and monitoring.

- Gains of Coriolis Effect Mass Flow Meters:

- Exquisite Correctness: They provide extremely accurate mass flow rate measurements, often with minimal disparities.

- Dependability: They deliver consistent and repeatable results, ensuring reliable process control.

- Broad Operational Scope: They can handle a wide range of flow rates, making them versatile for diverse applications.

- Multi-Fluid Capability: : Many Coriolis meters are designed to measure the flow of sundry fluids without recalibration.

Highly Accurate Flow Measurement Based on Coriolis

The Coriolis effect offers a robust method for achieving unmatched accuracy in mass flow measurement. It exploits rotational fluid dynamics within constrained tubing to generate lateral forces. Interpreting this force, precise determination of both bulk flow metrics becomes possible. Implementations based on such physics reveal unwavering tolerance variations in fluid viscosity. Differing from alternative methods, Coriolis provides direct mass flow readouts, removing dependency on fluid calibration. oil and gas exploration. Furthermore, Coriolis meters are known for their versatility, capable of measuring a wide range of fluid types, including both liquids and gases. Their ability to handle multiphase flow efficiently further enhances their appeal in diverse industrial settings.}Effective High Viscosity Fluid Analysis

Viscous fluid dynamics complicate conventional measurement approaches. can be inaccurate to provide reliable readings due to their inherent limitations in handling dense and sluggish materials. exceptional solution by leveraging the principles of inertia and rotational force. A specialized sensor, consisting of a pulsating tube, generates motions that induce a phase shift proportional to the mass flow rate. This inherent sensitivity to mass flow makes Coriolis meters highly accurate and reliable even for robust fluids. The benefits of using Coriolis technology extend beyond accuracy. tools offer adaptability in measuring a diverse set of fluids, including oils, mixtures, and slurries. Additionally, their inherent reliability ensures minimal maintenance high viscosity oil flow meter and extended operational endurance.Advanced Mass Flow Control for Thick Fluids

Within manufacturing requiring exact precision, coriolis mass flow meters excel as a preferred alternative. These meters exploit the Coriolis effect to assess mass flow rate with extraordinary fidelity across a considerable range of fluid densities. Importantly, coriolis meters outperform in handling high-viscosity liquids, where standard flow meter technologies often lag.

It stability makes them appropriate for operations such as oil and gas, chemical processing, food and beverage, and life sciences, where precise flow measurement of thorough fluids is key.

- Also, coriolis meters deliver additional advantages like:

- Continuous flow monitoring: Enabling real-time process control and optimization.

- Quantifying not only mass flow rate but also density, temperature, and circulation rate.

- Signal processing: Supporting seamless integration with process control systems.

Clear Flow Quantification: A Guide to Coriolis Mass Flow Meters

Mass flow sensors based on Coriolis are lauded for unmatched flow quantification. These flow meters depend upon Coriolis forces influencing motion inside rotational systems. By through with carefully measuring this deflection, Coriolis meters can are able to have the capability to determine both the mass flow rate and the density of the flowing fluid. This makes them an invaluable tool in a wide range of applications, from industrial process control to scientific research.Coriolis-Based Industrial Flow Solutions

Coriolis systems overhaul industrial metering through precise and robust operation. It leverages spinning tube mechanics and Coriolis momentum shifts for precise flow evaluation. It provides unparalleled accuracy required for delicate control processes.Meters perform reliably amid fluctuating fluid characteristics including density and agitation. Strong build quality translates to stable operation and reduced downtime.

- As well, Coriolis meters provide valuable insights into process system industrial parameters like flow direction and temperature, enabling comprehensive process monitoring and control.

- In summary, Coriolis technology represents a significant advancement leap forward breakthrough in industrial flow metering, empowering industries to optimize processes, enhance product quality, and achieve greater operational efficiency effectiveness productivity.

Broader Application Scope of Coriolis Instruments

These meters present distinct techniques extending past conventional density and thickness reliance. They detect mass transfer by tracking inertial effects in oscillating pipes. They assess flow mass and density from fluid-induced sensor motion patterns. These attributes qualify them as indispensable tools across applications demanding precision.- For example: the measurement of high-value liquids fluids substances like chemicals, pharmaceuticals, and food products.

- Also: Coriolis meters can handle manage process highly viscous thick resistant fluids with minimal little slight impact on accuracy.

Enhanced Measurement Stability in Extreme Flows

They serve optimally when confronted with fluidic and environmental hurdles. Built to withstand fluctuations and disturbances, they supply unmatched precision. Unlike traditional conventional standard flow meters that can be affected by influenced by susceptible to factors like viscosity changes or density fluctuations, Coriolis meters operate on the principle of inertia and momentum, offering providing delivering a reliable consistent dependable measurement regardless of these variables parameters factors.This makes results in enables them ideally suited perfectly positioned uniquely qualified for applications in industries like oil and gas, chemical processing manufacturing production, and even water treatment waste management environmental monitoring.- In addition, their ability to measure both flow rate and density simultaneously provides valuable critical essential insights into the process, aiding in optimization efficiency improvement process control.

- Ultimately, Coriolis meters represent a robust powerful effective solution for accurate flow measurement in extreme harsh challenging environments. Their versatility adaptability flexibility and inherent accuracy make them an indispensable crucial essential tool for various industries.

Mastering Fluid Measurement Difficulties Using Coriolis

Such meters grant advanced capabilities for managing bulky and dense fluids. Their unique innovative advanced operating principle, based on the Coriolis effect, allows enables facilitates precise measurement determination estimation even in challenging turbulent difficult flow conditions situations environments. By analyzing examining interpreting the deflection deviation movement of a flowing moving transiting fluid within the meter, these devices accurately precisely faithfully quantify measure determine mass flow rates with minimal little negligible influence from factors such as temperature pressure density.

- This Such These robustness durability reliability strength stability toughness solidness makes Coriolis meters ideal appropriate suitable for a wide broad diverse range of applications, including the processing handling manipulation of chemicals materials substances, foodstuffs agriproducts products, and pharmaceutical medicinal healthcare solutions.

- Furthermore Moreover Additionally Besides What's more In addition Also As well, Coriolis meters provide offer furnish a high level significant degree substantial amount of repeatability consistency accuracy, ensuring reliable trustworthy dependable data for process control monitoring optimization.

- Consequently Therefore As a result, they are essential vital crucial tools for industries sectors businesses that demand require need precise measurement quantification determination of fluid flow in complex challenging critical operating settings situations environments.

Enhanced Coriolis Performance with Viscous Media

Particularly in industrial chemical manufacturing settings where high-viscosity fluids flow travel are transported, these meters excel due to their unique operating principle. Unlike traditional sensors meters devices that rely on pressure or velocity measurements, Coriolis meters leverage the inertial forces centrifugal force mechanical properties exerted on a vibrating tube as fluid passes through flows around enters it. This direct measurement of mass flow provides unparalleled precision accuracy determination, even in the presence of fluctuating viscosity density temperature. Moreover Furthermore Additionally, their robust construction ensures guarantees promotes long-term performance and minimal maintenance, making them a reliable dependable trustworthy choice for demanding high-viscosity applications.